SCHUTTE MEYER ASHWATH ALLOYS PVT LTD

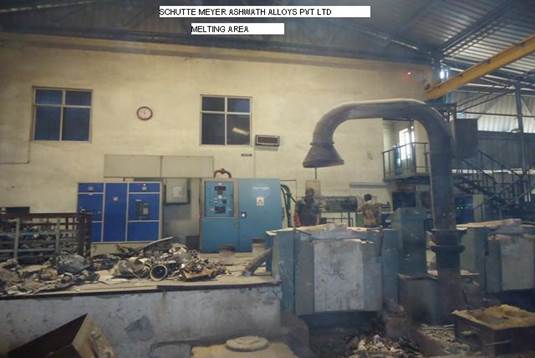

Melting

- Inductotherm 550 kW control panel / IGBT.

- 2000 kg, 1000 kg and 500 kg nominal capacity melting crucibles.

- 2400 kg max liquid metal available.

- Spectrometer and liquid metal temperature measurement.

- Oil Fired ladle preheating arrangement with infra red temperature measurement.

- Bottom pouring and lip pouring ladles.

- Only CRCA scrap is used.

- Carbon steel will have S&P always less than 0.02%.

- Very consistent chemistry controlled within narrow ranges.

- All input weighed before charging.

- Bath Sample analysis.

- Addition calculated based on target chemistry.

- Final Sample chemistry verified before tapping metal.

- Liquid metal temperature checked before tapping.

- Sample drawn from pouring ladle for chemistry certification.

- Ladle preheating checked by non-contact thermometer.

- Pouring time monitored for sample and all critical castings.

Get in Touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

Email us

Opening Hours

Monday - Saturday

9:00 am to 5.00 pm

9:00 am to 5.00 pm

Address

SF No.173, Appanaickenpatti Post, Sulur,

Coimbatore - 641402.

Tamil Nadu, INDIA

Coimbatore - 641402.

Tamil Nadu, INDIA